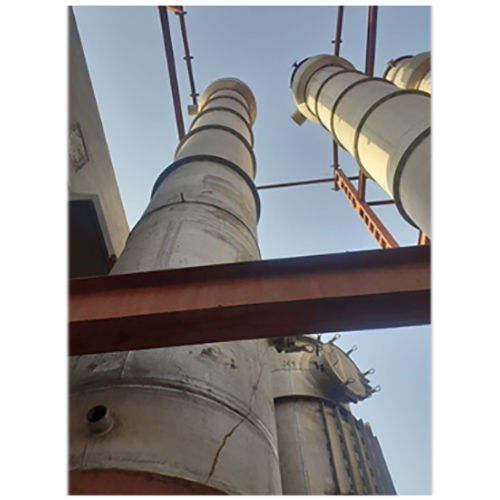

Milk evaporation plant

350000 INR/Unit

Product Details:

- Model No MEE-SS/2024

- Efficiency (%) Up to 98%

- Motor Power 7.5-20 HP based on scale

- Driven Type Electric

- Frequency 50/60 Hz

- Production Capacity Customizable

- Installation Guideline On-site installation and commissioning by expert team

- Click to View more

X

Milk evaporation plant Price And Quantity

- 350000 INR/Unit

- 1 Unit

Milk evaporation plant Product Specifications

- 7.5-20 HP based on scale

- Electric

- Up to 98%

- MEE-SS/2024

- Multiple Effect Evaporator for Milk

- Variable, up to 1440 RPM

- Yes

- Customizable

- 50/60 Hz

- Stainless Steel (SS304/SS316)

- Electric

- Up to 95C

- On-site installation and commissioning by expert team

- 500 LPH to 20,000 LPH

- High-efficiency evaporation, low energy consumption, hygienic design, easy cleaning

- Milk Evaporation Plant

- Automatic

- Metallic Silver

- Optimized as per plant design

- Vacuum pump, condenser, pumps, instrumentation package

- 380-440 V

- Mirror/Matte Polished

- Depends on capacity, typically 25-100 kW

- Automatic

- PLC Controlled

- Customized as per requirement

- Milk concentration, dairy processing, production of condensed and evaporated milk

- Varies according to capacity, approx. 2000-7000 kg

Milk evaporation plant Trade Information

- Cash on Delivery (COD)

- Standard

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

The manufacturing process for the evaporated milk involves precision standardization of the fat content and the dry solids contents. This is followed by heat treatment which partly destroys the microbes present in the milk. Checks are carried out on the coagulation stability of the milk before it is packaged in the sterilized cans. The product is then placed in an autoclave for sterilization. Finally the cans are cooled before storage.Efficient Milk Concentration

This evaporation plant is engineered for rapid and uniform milk concentration, using optimized multi-effect evaporation technology to minimize steam and power consumption. Its capacity can be tailored from 500 to 20,000 liters per hour, making it suitable for both medium and large-scale dairy operations. The use of AISI SS316 for product-contact parts ensures exceptional hygiene and product integrity throughout the process.

Automated Control and Hygiene

The system features a PLC-based automatic control for streamlined operation and consistent product quality. Cleaning is fully automated via CIP (Clean-in-Place), reducing manual intervention and downtime. Mirror or matte polished surfaces further enhance cleanliness, and all critical factors such as temperature, pressure, and foam are monitored and managed for optimal safety and efficiency.

Optimized Energy and Maintenance

With steam consumption as low as 0.25-0.5 kg per kg of evaporated water, the plant is highly energy-efficient. Noise levels stay below 80 dB(A) for a quieter working environment. The design prioritizes easy access for maintenance and quick part replacement, further supported by readily available spare components for uninterrupted operation.

FAQ's of Milk evaporation plant:

Q: How does the milk evaporation plant optimize energy consumption during operation?

A: The plant utilizes advanced multi-effect evaporation technology, which recycles heat across stages to minimize steam use-typically between 0.25 and 0.5 kg steam per kg of evaporated water. This results in lower operational costs and enhanced energy efficiency.Q: What safety and hygiene features are included in the system?

A: Safety is ensured through overpressure protection, emergency stops, and accurate temperature sensors. Hygiene is maintained with full CIP (Clean-in-Place) capability, use of AISI SS316 stainless steel for all product-contact parts, and mirror/matte surface finishing to prevent bacterial growth.Q: Where can the milk evaporation plant be installed, and who handles the setup?

A: Installation and commissioning are carried out by an expert team on-site at the customer's facility. The plant is suitable for dairy processing centers, milk concentration units, and factories producing evaporated or condensed milk, with dimensions and layout fully customized to fit available space.Q: What is the process for cleaning and maintaining the plant?

A: Cleaning is automated using a CIP system that efficiently sanitizes all product-contact surfaces. Maintenance is minimal due to the robust stainless steel construction and accessible design, plus spare parts are readily supplied for quick servicing when necessary.Q: How is foam formation controlled during milk evaporation?

A: Foam is managed either automatically by the control system or manually, based on process requirements. This ensures smooth operation and prevents issues such as product overflow or inefficiencies in evaporation.Q: What are the key benefits of using this milk evaporation plant?

A: Benefits include high operational efficiency (up to 98%), low energy and power consumption, full automation with PLC control, reliable safety features, and exceptional hygiene standards. The plant also supports various capacities and application needs in dairy production.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email