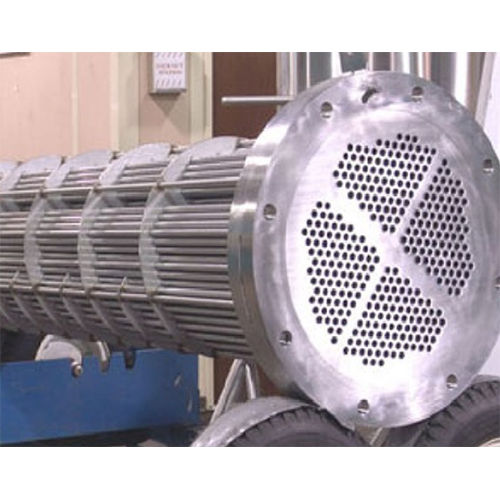

Stainless Steel Vessel Gas Cooler

165000 INR/Piece

Product Details:

- Thickness 8 mm

- Temperature -20C to 200C

- Diameter 600 mm

- Max. Capacity 1000 L

- Number of Pipe 18

- Max Pressure 1.0 MPa

- Air Volume 1200 m/h

- Click to View more

X

Stainless Steel Vessel Gas Cooler Price And Quantity

- 165000 INR/Piece

- 1 Piece

Stainless Steel Vessel Gas Cooler Product Specifications

- Horizontal cylindrical vessel

- 415 V

- 1200 mm x 600 mm x 750 mm

- 8 m/h

- 8 mm

- -20C to 200C

- 600 mm

- 1000 L

- 3 kW

- 18

- 1.0 MPa

- 0.6 MPa

- New

- 1200 m/h

- 150 kg

Stainless Steel Vessel Gas Cooler Trade Information

- Cash on Delivery (COD)

- Standard

- Eastern Europe, Western Europe, Middle East, Africa, Asia, Australia, Central America, North America, South America

- All India

Product Description

A vessel gas cooler, specifically a shell and tube gas cooler, is a type of heat exchanger used to cool gases or vapors in industrial processes. It consists of a cylindrical shell with a bundle of tubes running through it. The gas to be cooled flows through the tubes, while the cooling medium, typically water or a refrigerant, circulates around the tubes within the shell.The gas enters the cooler through an inlet connection and passes over the external surface of the tubes. As it comes into contact with the cooler tubes, heat is transferred from the gas to the cooling medium. This causes the gas to cool down and potentially condense.

The cooling medium, circulating inside the shell, absorbs the heat from the gas and exits the cooler through an outlet connection. It may be cooled by external means, such as a cooling tower or refrigeration system, before being recirculated back into the shell.

The design of the shell and tube gas cooler allows for efficient heat transfer due to the large surface area provided by the tube bundle. The tube bundle is typically removable, allowing for easy cleaning and maintenance.

Shell and tube gas coolers are widely used in various industries, including oil and gas, petrochemical, chemical processing, and power generation. They are employed in applications such as gas compression, gas separation, vapor recovery, and gas conditioning.

These coolers can be customized to meet specific requirements, including variations in shell and tube materials, tube arrangement, and overall dimensions. It is important to consider factors such as gas composition, pressure, temperature, and desired cooling capacity when selecting a shell and tube gas cooler for a particular application.

Superior Material Quality

Constructed from premium SS304/SS316 stainless steel, this gas cooler ensures longevity, resistance to corrosion, and safe cooling in demanding industrial environments. The polished finish not only adds durability but also simplifies routine cleaning and maintenance, maintaining its performance over time.

Optimized for Industrial Efficiency

With a heat exchange area of 8.5 m, a maximum capacity of 1,000 liters, and the ability to operate at air volumes up to 1,200 m/h, our gas cooler meets the rigorous cooling requirements of various industrial processes. Its robust design accommodates pressure ratings of up to 1.0 MPa and temperatures ranging from -20C to 200C.

Customizable Performance and Support

We offer optional thermal insulation tailored to your operational needs, ensuring greater energy efficiency and safety. Backed by a manufacturers 12-month warranty, our service, support, and supply network across India ensures peace of mind and continuous uptime for your operations.

FAQs of Stainless Steel Vessel Gas Cooler:

Q: How is the Stainless Steel Vessel Gas Cooler installed in an industrial setting?

A: The gas cooler is designed for floor mounting and features flanged connections to ensure a secure and straightforward installation process within your production line or gas handling system.Q: What materials are used in constructing this gas cooler and why?

A: The vessel is made from SS304 or SS316 stainless steel. These materials offer excellent resistance to corrosion, high strength, and suitability for a broad temperature and pressure range, making them ideal for industrial gas cooling.Q: When should the optional insulation feature be considered?

A: Insulation is recommended if your cooling process operates at extreme temperatures or requires enhanced energy efficiency. It helps maintain consistent output temperatures and reduces heat loss for sensitive applications.Q: Where is this gas cooler suitable to be deployed?

A: This cooler is optimal for a wide range of industrial environments across India, including chemical plants, refineries, and manufacturing facilities, wherever efficient gas cooling and corrosion resistance are needed.Q: What is the process involved in cooling gas using this vessel?

A: Gas enters the vessel through the flanged inlet, flows over the heat exchange tubes, and transfers heat to the cooling medium circulating within. This process allows efficient heat removal, controlled by the vessels large heat exchange area and high flow rate.Q: How does this product benefit my operation?

A: The vessels efficient design ensures rapid and effective cooling, prolonged operational life thanks to corrosion resistance, and reduced downtime with its durable construction and manufacturer-backed 12-month warranty.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email