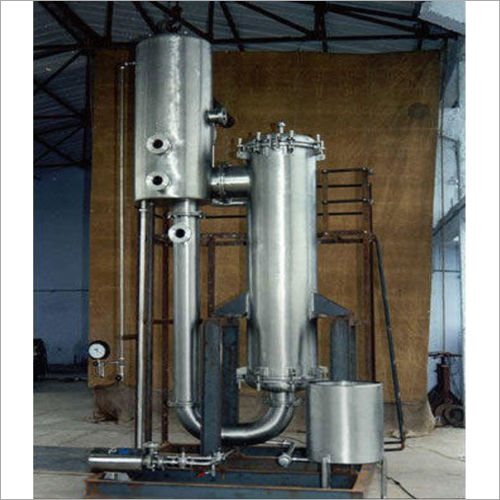

Agitated Thin Film Evaporator

Product Details:

- Pressure Vacuum to Atmospheric

- Sealing Mechanical Seal

- Condition New

- Process Agitation, Thin Film Evaporation

- Power Source Electric

- Application Pharmaceutical, Chemical, Food Processing, Waste Management

- Material Stainless Steel 316/304

- Click to View more

X

Agitated Thin Film Evaporator Product Specifications

- 7.5 kW - 40 kW

- New

- Stainless Steel 316/304

- Depends on model/capacity

- Vacuum to Atmospheric

- 220-240 V

- Customizable as per requirement

- Mechanical Seal

- Pharmaceutical, Chemical, Food Processing, Waste Management

- Agitation, Thin Film Evaporation

- Electric

Product Description

We are delivering a wide array of Agitated Thin Film Evaporator to clients. This evaporator is basically utilized to separate the components of a process liquid. It is useful to apply heat to a liquid which cause to evaporation and leave low volatile particles. It is recommended for liquids which are not able to handle properly because of higher sensitivity. Agitated Thin Film Evaporator aids to reduce the liquid residence time in the evaporator. It is a corrosion free unit which quickly separates the volatile.

Efficient Thin Film Evaporation Process

Our Agitated Thin Film Evaporator ensures gentle yet thorough mixing and spreading of the feed material across heated surfaces, generating a thin, uniform film for optimal heat transfer and separation. The adjustable film thickness and controlled agitation allow for consistent product quality, even with sensitive or viscous solutions. Its vertical orientation, robust construction, and choice of mirror or matt finish ensure both efficient processing and easy cleaning.

Versatile Design for Diverse Applications

Engineered for flexibility, the evaporator accommodates a wide range of feed capacities and heating options to suit diverse operational needs. PLC/manual control interfaces provide precise system management, while multiple mounting and discharge types facilitate integration into any process line. Stainless steel construction guarantees strong resistance to corrosion, making this evaporator a reliable choice for industries including pharmaceuticals, chemicals, food processing, and more.

Advanced Safety and Easy Maintenance

Safety and hygiene are paramount. This evaporator includes overload protection, an emergency stop feature, and is fully compatible with CIP (Clean in Place) systems, reducing downtime for cleaning. The machine can be supplied with customized dimensions and power ratings, ensuring a perfect fit for your specific process requirements.

FAQ's of Agitated Thin Film Evaporator:

Q: How does an Agitated Thin Film Evaporator work?

A: The Agitated Thin Film Evaporator operates by spreading liquid feed into a thin film on the heated inner surface of a vertical cylindrical vessel using a rotating agitator. This increases the surface area and enhances heat and mass transfer, allowing rapid evaporation at lower temperatures. Adjustable film thickness and rotational speeds ensure optimal performance for various product viscosities and desired concentration levels.Q: What industries can benefit from using this evaporator?

A: Industries such as pharmaceuticals, chemicals, food processing, and waste management benefit greatly from this evaporator's ability to process heat-sensitive or viscous feeds efficiently. Its corrosion-resistant construction, flexible control options, and precise evaporation process make it suitable for a wide range of products, from active pharmaceutical ingredients to food extracts and industrial waste.Q: When should a thin film evaporator be preferred over conventional evaporators?

A: A thin film evaporator should be chosen when working with materials that are heat sensitive, prone to fouling, highly viscous, or when quick and efficient evaporation is necessary. Its gentle agitation, precise temperature control (up to 180C), and low residence time make it ideal for products that could degrade or solidify in traditional evaporators.Q: Where can the evaporator be installed and what are the available mounting options?

A: This evaporator can be installed in various settings, as it is available in both skid-mounted and floor-mounted configurations. Its compact and customizable design allows seamless integration into existing production lines within manufacturing plants, laboratories, or pilot plants.Q: What are the control and safety features included in the evaporator?

A: The evaporator can be operated via a sophisticated PLC-based automated system or with manual controls. It is equipped with key safety features such as overload protection, emergency stop, and mechanical sealing to prevent leaks. These ensure safe operation while minimizing operator intervention and risk.Q: How is cleaning and maintenance managed for this equipment?

A: The evaporator is fully compatible with CIP (Clean in Place) systems, allowing for efficient, automated cleaning without disassembly. The mirror or matt finish surfaces and stainless steel construction further facilitate easy maintenance, ensuring hygiene standards are consistently met with minimal downtime.Q: What are the main benefits of using a thin film evaporator in processing applications?

A: Among the primary benefits are high thermal efficiency, rapid evaporation rates, excellent product quality especially with heat-sensitive materials, customizable operation parameters, and robust construction for long-term use. It also offers flexible integration, ease of cleaning, and improved process safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email