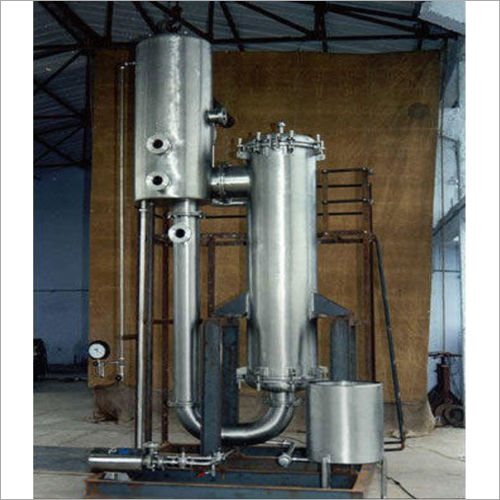

Short path evaporator

500000 INR/Piece

Product Details:

- Sealing Double Mechanical Seal

- Pressure 0.1 mbar (Vacuum Operation)

- Condition New

- Process Short Path Distillation

- Power Source Electric

- Application Essential Oils, Pharmaceuticals, Chemicals

- Material Borosilicate Glass / Stainless Steel

- Click to View more

X

Short path evaporator Price And Quantity

- 1 Piece

- 500000 INR/Piece

Short path evaporator Product Specifications

- 220 V

- Electric

- 700 mm x 400 mm x 950 mm

- Essential Oils, Pharmaceuticals, Chemicals

- 0.1 mbar (Vacuum Operation)

- Borosilicate Glass / Stainless Steel

- 75 kg

- New

- Double Mechanical Seal

- 1500 W

- Short Path Distillation

Short path evaporator Trade Information

- Cash on Delivery (COD)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

Short Path Evaporation is a specialized process for gently processing heat sensitive, high boiling products, utilizing an internal condenser and Wiped Film rotor technology. The internal condenser of the Short Path Evaporator provides minimal pressure drop, permitting high vacuum operation down to 0.001 mbar.

VEPL deals in all types of Evaporatoras per client requirement. All material of construction available in this equipment.

High-Performance Distillation Technology

Utilizing state-of-the-art short path distillation principles, our evaporator offers precise temperature control up to 250C with a digital display and automated PID controller. This setup ensures efficient separation while preserving product integrity. The vacuum operation and integrated condenser enhance evaporation efficiency and reduce operational costs, making this equipment ideal for sensitive and valuable compounds.

Robust Construction and Safety

Manufactured with a combination of borosilicate glass and SS 316 stainless steel, the evaporator guarantees excellent chemical resistance, mechanical strength, and a prolonged lifespan. The double mechanical seal and heavy-duty motor ensure leak-free operation even under continuous workloads. Automated controls, temperature and vacuum indications further bolster safety and consistency in all processing environments.

User-Friendly Operation and Advanced Control

The digital control panel is designed for intuitive user experience, providing accurate readings of temperature and vacuum levels at all stages. The adjustable rotation speed and easy feed, distillate, and residue outlets aid seamless process adjustments. Additionally, the efficient cooling and PTFE wiper system contribute to high-yield, minimal loss operation for industrial users.

FAQ's of Short path evaporator:

Q: How does the integrated high-efficiency condenser benefit the short path evaporator process?

A: The integrated high-efficiency condenser rapidly cools vapors, enabling immediate condensation and efficient separation. This minimizes product loss, ensures high purity distillate, and reduces operational time by maintaining a condensed pathway within the system.Q: What types of materials can be processed with this short path evaporator?

A: This evaporator is suitable for heat-sensitive and high-value compounds such as essential oils, pharmaceuticals, and specialty chemicals. Its design ensures gentle processing, minimizing thermal degradation and preserving product quality.Q: When should operators adjust the rotation speed of the evaporator?

A: Adjusting the rotation speed (50-250 rpm) is recommended to optimize film thickness and evaporation rates based on the viscosity and volatility of the feed material. This helps achieve efficient separation while preventing material build-up or degradation.Q: Where is this short path evaporator manufactured and supported?

A: The short path evaporator is manufactured, supported, and supplied in India. Customers across the country benefit from accessible service networks and prompt technical support provided by the manufacturer.Q: What is the process of operating this short path evaporator?

A: Operation involves feeding the sample through the 25 mm inlet, setting the desired rotation speed and temperature using the digital PID control panel, and initiating vacuum operation. The internal condenser collects distillate, while residue exits via the designated outlet. Continuous monitoring is provided by digital displays.Q: How does the PTFE wiper system enhance performance?

A: The PTFE wiper system ensures a uniform, thin film of material on the heated surface, maximizing surface area for evaporation and preventing material sticking or burning. This results in higher yields and consistent quality over extended operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email