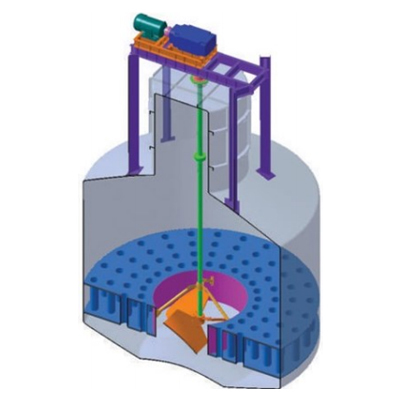

anchor impeller

45000 INR/Piece

Product Details:

- Production Capacity Batch / continuous, as designed

- Power Rating Varies as per model

- Frame Type Mounting flange or shaft mount

- Lubricating System Grease lubricated bearing (if applicable)

- Noise Level <75 dB

- Frequency 50/60 Hz

- Features Rugged construction, high efficiency, easy installation, suitable for high viscosity media

- Click to View more

X

anchor impeller Price And Quantity

- 1 Piece

- 45000 INR/Piece

anchor impeller Product Specifications

- Atmospheric or as specified (impeller itself does not generate pressure)

- Uniform mixing, subject to impeller design

- Electrical terminal box

- 230V/415V AC, 50/60Hz

- 0.5 HP to 15 HP (as per process requirement)

- Metallic/Steel grey

- Impeller / Agitator

- As per agitator design, typically 0.5 HP to 15 HP

- Custom as per tank size and mixing requirement

- Anchor Impeller

- Automatic/Semi-Automatic

- Direct / Gear drive

- <75 dB

- Grease lubricated bearing (if applicable)

- 50/60 Hz

- Motor driven (Electric)

- Mechanical Mixing

- Mounting flange or shaft mount

- Batch / continuous, as designed

- Varies as per model

- As specified by manufacturer

- Air cooled / Not applicable

- Polished/Coated Mild Steel or Stainless Steel

- Mixing viscous materials, liquids, resins, paints, chemicals, adhesives, food and pharma blending

- Rugged construction, high efficiency, easy installation, suitable for high viscosity media

- Depends on impeller size, typically 1050 kg

- Up to 100C (or as per material)

- Manual / PLC based control (optional)

anchor impeller Trade Information

- Cash on Delivery (COD)

- Standard

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

An impeller designed for higher viscosity products. An anchor is normally "U" shaped, and follows the contour of the tank, with minimal clearance between the outside of the blade and the tank wall. Anchor impellers are specifically designed to fit the particular process.

VEPL deals in all types of Impeller as per client requirement. All material of construction available in this equipment.

Robust Design for High Viscosity Mixing

The anchor impeller's rugged construction and continuous edge design ensure efficient agitation of viscous liquids, resins, adhesives, and other challenging materials. Customized by shaft length and diameter, it supports tanks up to 30,000 liters, offering outstanding reliability across demanding mixing operations. The choice of SS304, SS316, or Mild Steel meets process compatibility and performance needs.

Flexible Installation & Customization

With options for top or side entry mounting, as well as flange, welded, or threaded installation, the anchor impeller fits seamlessly into new or existing tank setups. Comprehensive customization allows you to specify size, material grade, and surface finish-guaranteeing optimal integration into your unique process.

Reliable, Safe & Efficient Operation

Designed for automatic or semi-automatic operation, the anchor impeller features motor overload protection, grease-lubricated bearings, and a noise level below 75 dB. Its optimized structure enhances mixing efficiency while supporting atmospheric or specified pressure conditions, all while promising easy, long-lasting service life over five years under normal operation.

FAQ's of anchor impeller:

Q: How is the anchor impeller installed in the mixing tank?

A: The anchor impeller can be installed using flange, welded, or threaded mounting methods, suitable for either top or side entry based on tank design and operational requirements. Customization ensures compatibility with a variety of tank sizes and configurations.Q: What are the main benefits of using an anchor impeller for high viscosity fluids?

A: Anchor impellers are specifically designed to provide uniform, efficient mixing of high-viscosity materials, such as adhesives, paints, resins, and other semi-solid liquids. Their robust, continuous edge helps prevent dead zones and ensures thorough agitation throughout the tank.Q: What customization options are available for the impeller?

A: You can customize the anchor impeller's size (shaft length, diameter), material grade (SS304, SS316, or Mild Steel), mounting type, surface finish (matte/glossy), and installation style. This makes it suitable for a wide range of process, tank, and industry-specific requirements.Q: Where can anchor impellers be used?

A: Anchor impellers are used in a variety of industries including chemical, pharmaceutical, food, paint, adhesives, and cosmetics. Their versatility makes them ideal for blending, homogenization, and dispersion in both batch and continuous production environments.Q: How long is the expected service life of the anchor impeller?

A: Under normal operating conditions and with proper maintenance, the anchor impeller is designed to last over five years, maintaining efficient mixing performance throughout its service life.Q: What is the process for selecting the appropriate anchor impeller model?

A: Selecting the right impeller involves evaluating tank volume, media viscosity, required power, mounting preference, material compatibility, and specific mixing objectives. Manufacturers typically assist with model recommendations based on detailed process information.Q: What safety features are included with the anchor impeller assembly?

A: If supplied as an assembly with the motor, the system includes overload protection to safeguard against excessive loads or operational issues. Additional features like manual or PLC-based control systems can be integrated for enhanced process safety and monitoring.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email