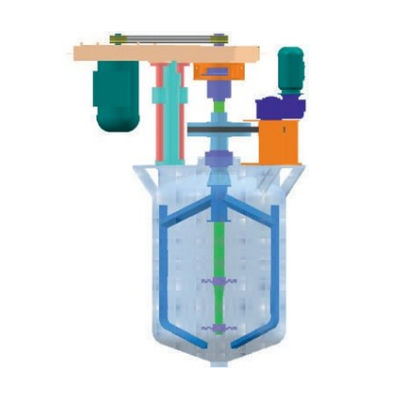

Mechanical Pan Circulator (MPC)

Product Details:

- Voltage 220-240V

- Machine Type Pan Circulator

- Frequency 50-60 Hz

- Noise Level Low

- Frame Type Robust metal frame

- Accuracy High

- Power Rating Variable based on motor specifications

- Click to View more

X

Mechanical Pan Circulator (MPC) Product Specifications

- 50-60 Hz

- Low

- Robust metal frame

- 1 year

- Electric

- Pan Circulator

- 220-240V

- Pre-lubricated components

- Manual/Automated Control

- Ambient Cooling

- High mixing throughput

- Motor-driven system

- Mechanical Linkage

- Industrial Circulation Machine

- Atmospheric pressure

- Industrial mixing and circulation

- Purple and Blue

- Continuous Operation

- Variable based on motor specifications

- Efficient mixing durable frame easily adaptable

- Power-coated for corrosion resistance

- Ambient temperature

- Varies based on application

- Mechanical agitation

- Dependent on size and configuration

- High

Product Description

Mechanical pan circulators (MPC) is employed to move a fluid throughout a system. It is used to maintain a consistent temperature within the system, and the fluid is typically a liquid or gas. A pump circulates the fluid, and the thermostat governs the pump. In order to maintain the proper temperature, the thermostat regulates the pump's on and off times. The efficiency of the crystallisation process is increased in the sugar business by the use of mechanical pan circulators (MPC). It boosts pan yield while reducing boiling time and sugar colour. This device is utilised in vacuum pans to produce better and stronger massecuite circulation, which improves heat transfer and shortens the boiling time.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email