Hydrofoil impeller

150000 INR/Piece

Product Details:

- Drive Direct / Gear drive

- Frame Type Custom Mountable

- Features Energy efficient, corrosion resistant, lightweight design

- Accuracy High mixing efficiency

- Connectivity Options Direct shaft connection

- Model No Hydrofoil Series

- Operating Temperature Up to 120C

- Click to View more

X

Hydrofoil impeller Price And Quantity

- 150000 INR/Piece

- 1 Piece

Hydrofoil impeller Product Specifications

- Low to Medium

- Industrial Impeller

- As per client specification

- As per drive selection

- Varies as per size/design

- Metallic Silver

- 0.5 HP & Above

- Varies by model (e.g. Blade Dia. 150 mm - 1200 mm)

- 50/60 Hz

- 220-440 V

- Hydrofoil Impeller

- Mixing, blending, liquid agitation in chemical & process industries

- High mixing efficiency

- Polished/Coated

- Direct shaft connection

- Direct / Gear drive

- Custom Mountable

- Energy efficient, corrosion resistant, lightweight design

- Motor Driven

- Advanced Fluid Dynamics

- Customizable as per application

- Continuous

- Up to 120C

- Hydrofoil Series

- Manual/Automated

- Low

Hydrofoil impeller Trade Information

- Cash on Delivery (COD)

- Standard

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

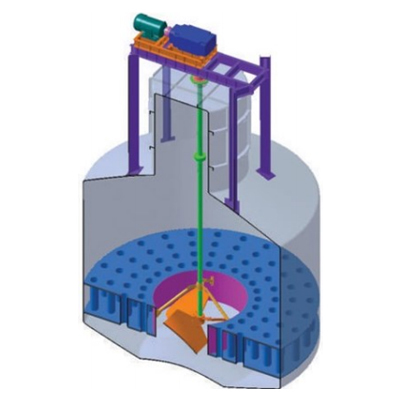

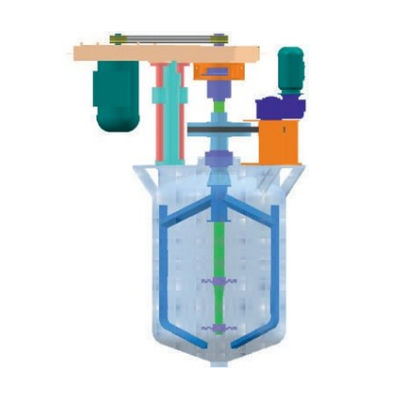

High efficiency impellers designed to maximize fluid flow and minimize shear rate. 3 or 4 tapering twisted blades, cambered and sometimes provided with rounded leading edges. The blade angle at the tip is lower than that at the hub. Resultant flow is streamlined.VEPL deals in all types of Impeller as per client requirement. All material of construction available in this equipment.

Exceptional Performance & Durability

Engineered with advanced fluid dynamics technology, the Hydrofoil impeller provides highly efficient mixing and blending while resisting corrosion. Its polished and coated surface treatment ensures longevity even under demanding conditions, with a robust operational capability up to 120C.

Flexible Configuration & Application

You can specify blade material, angle, size, and mounting type to suit unique process requirements. Whether in pharmaceuticals, chemicals, or water treatment, the impeller offers custom solutions for different tank dimensions and agitation needs with production capacity adjusted as per client specifications.

FAQ's of Hydrofoil impeller:

Q: How does the Hydrofoil impeller enhance mixing efficiency in industrial processes?

A: The Hydrofoil impeller employs advanced blade pitch optimization (standard 25-35 degrees) and fluid dynamics, creating effective flow patterns for thorough mixing, blending, and agitation of liquids. This design improves homogenization and reduces power consumption, resulting in consistent product quality.Q: What materials are available for the impeller blades, and how do they resist corrosion?

A: Blades are manufactured from high-grade stainless steel 304/316 or special alloys, providing excellent resistance to chemical and environmental corrosion. This ensures reliable operation and extends service life, particularly in harsh process conditions.Q: When should I consider customization for my Hydrofoil impeller?

A: Customization is recommended when your process requires specific blade size, pitch, material, dimension, or mounting type. The impeller can be tailored for different tank sizes, viscosity levels, and application parameters to optimize performance in your sector.Q: Where can Hydrofoil impellers be used?

A: Hydrofoil impellers are suitable for pharmaceuticals, biotechnology, chemicals, and water treatment industries. They are used in mixing, liquid blending, and agitation applications across industrial processes where precision and reliability are critical.Q: What is the process for ordering and integrating a Hydrofoil impeller into my system?

A: Start by specifying your application needs including blade material, dimensions, mounting type, and power requirements. Manufacturers and suppliers in India assist with selection, customization, and integration for efficient installation and optimal operation.Q: How does the energy-efficient design of the Hydrofoil impeller benefit operations?

A: The lightweight and streamlined blade geometry reduces drag, requiring less motor power for the same level of mixing. This lowers energy costs and enhances the impeller's operational efficiency over its extended service life.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email