Modular cooling tower

1200000 INR/Piece

Product Details:

- Air Volume 11000 m/h

- Thickness 5 mm

- Number of Pipe 4

- Temperature 5C to 60C

- Max Pressure 2.0 MPa

- Diameter 1200 mm

- Max. Capacity 100 TR

- Click to View more

X

Modular cooling tower Price And Quantity

- 1 Piece

- 1200000 INR/Piece

Modular cooling tower Product Specifications

- 5 mm

- 350 kg

- 1500 mm x 1500 mm x 1800 mm

- 4

- 5C to 60C

- 11000 m/h

- 415 V

- 2.0 MPa

- New

- 1200 mm

- 50 m/h

- 100 TR

- 1.6 MPa

- 5.5 kW

- Modular, FRP Body

Modular cooling tower Trade Information

- Cash on Delivery (COD)

- Standard

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

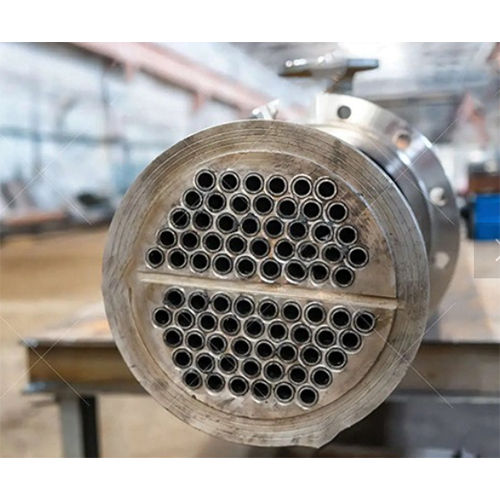

Product Description

A cooling tower is a specialized heat exchanger in which air and water are brought into direct contact with each other in order to reduce the waters temperature. As this occurs, a small volume of water is evaporated, reducing the temperature of the water being circulated through the tower.

VEPL deals in all types of Utility as per client requirement. All material of construction available in this equipment.

Efficient Induced Draft Cooling

Our modular cooling tower utilizes the induced draft method to maximize heat dissipation with minimal energy usage. The aluminum alloy fan and precision-engineered spray nozzle water distribution ensure rapid, uniform cooling, making it ideal for large-scale industrial and HVAC applications.

Low Noise, High Performance

Operating at a noise level of 65 dB, this cooling tower offers a quieter working environment. The FRP body and PVC honeycomb fill enhance thermal performance while minimizing sound, ensuring your facility keeps cool without unwanted noise disruptions.

Durable, Modular Construction

Built with a galvanized steel frame and FRP body, the cooling tower boasts a robust structure and a 5 mm thickness for extended longevity. The modular design allows for easy installation, expansion, or maintenance, supporting diverse operational requirements across manufacturing and plant settings.

FAQ's of Modular cooling tower:

Q: How does the modular cooling tower achieve efficient cooling?

A: The tower employs an induced draft design, where the aluminum alloy fan draws air through PVC honeycomb fills. This maximizes heat transfer from the circulating water, while the spray nozzle system ensures even water distribution for enhanced efficiency.Q: What are the key benefits of using this cooling tower for industrial applications?

A: It offers a robust capacity of up to 100 TR, maintains low noise levels (65 dB), and features corrosion-resistant materials like galvanized steel and FRP. The modular construction allows easy scalability and maintenance, fitting a variety of industrial and HVAC needs.Q: When is this cooling tower suitable for installation in manufacturing plants?

A: This cooling tower is ideal for installation when you require consistent water temperature control within the 5C to 60C range, liquid flow rates up to 50 m3/h, and maximum pressures of 1.6 MPa, often necessary for process cooling or HVAC systems in manufacturing environments.Q: Where is the modular cooling tower commonly used?

A: It is widely deployed in HVAC systems, industrial cooling, and manufacturing plants throughout India. Its adaptability and robust design make it suitable for both new installations and facility upgrades.Q: What is the standard process for installing and maintaining this cooling tower?

A: Installation includes setting the modular FRP body on a prepared site, connecting inlet and outlet pipes (both 100 mm), and ensuring electrical connections for the 5.5 kW motor. Regular maintenance involves checking spray nozzles, inspecting the fan and fill material, and ensuring the IP55 motor operates efficiently.Q: How can users benefit from the noise reduction features of this cooling tower?

A: With a noise level capped at 65 dB, the system provides a quieter work environment, which is crucial in settings where reduced operational noise is a priority-helping improve overall workplace comfort and productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email