Steam jet ejector

150000 INR/Piece

Product Details:

- Working Temperature Up to 150C

- Features Corrosion resistant, simple maintenance, non-clogging

- Inlet/Outlet Customizable, Standard Flange

- Theory Jet Ejector

- Max Suction Up to 760 mmHg (Full Vacuum)

- Discharge Pressure Atmospheric or custom

- Mounting Type Horizontal/Vertical

- Click to View more

X

Steam jet ejector Price And Quantity

- 150000 INR/Piece

- 1 Piece

Steam jet ejector Product Specifications

- Steam

- Up to 760 mmHg (Full Vacuum)

- Custom to process requirements

- Atmospheric or custom

- Horizontal/Vertical

- Low

- Gasket Sealed

- Ejector

- Jet aspiration

- Up to 150C

- Corrosion resistant, simple maintenance, non-clogging

- Customizable, Standard Flange

- Jet Ejector

- ASME/Custom

- Distillation, Vacuum Packing, Chemical Processing, Power Plants

- Manual or automated steam control

- Multi-stage available, simple design

- Varies, typically DN25 to DN300

- Vacuum generation and gas removal

- Stainless Steel/Carbon Steel

- Dependent on design and steam pressure

- Steam Pressure up to 20 bar

- Self-priming

- Custom

- Powered by steam, no motor

Steam jet ejector Trade Information

- Cash on Delivery (COD)

- Standard

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

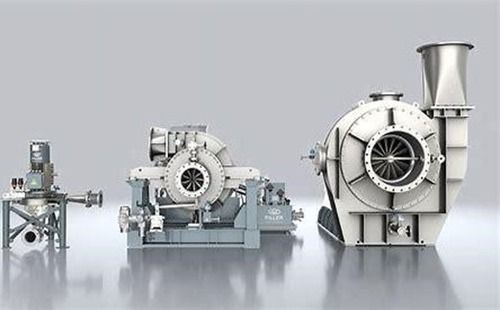

The steam ejector is a simple device consisting of three basic components, a motive steam nozzle, a suction chamber and a mixing diffuser. The motive steam enters the ejector through the motive fluid nozzle and is expanded into the mixing diffuser converting pressure energy into velocity energy.Superior Material & Construction

Featuring a high-grade stainless steel nozzle and either epoxy-painted or polished stainless/carbon steel body, these steam jet ejectors offer robust protection against corrosion. The gasket-sealed design and customizable inlet/outlet sizes ensure compatibility with a wide range of process solutions, supporting both horizontal and vertical mounting for flexible installation.

Wide-Ranging Applications

Engineered for use in vacuum generation and gas removal tasks, our steam jet ejectors perform efficiently in distillation, vacuum packing, chemical processing, and within power generation settings. Their operating medium-saturated or superheated steam-enables them to deliver optimal results across varying process conditions and industries.

Flexible Design and Maintenance

With a modular structure, users can select single, two-stage, or multi-stage setups to meet specific pressure and flow requirements. Their quick disassembly flanges facilitate straightforward inspection or maintenance, minimizing downtime. Each unit is customizable for flow, material, and pressure, making them an ideal solution for unique operational demands.

FAQ's of Steam jet ejector:

Q: How does a steam jet ejector operate for vacuum generation?

A: A steam jet ejector works by directing high-pressure steam through a nozzle, creating a jet that entrains gases or vapors from a process system. This mixture moves through a diffuser, resulting in a vacuum suitable for applications such as distillation or gas removal.Q: What materials are used in the construction of these steam jet ejectors?

A: The nozzle is constructed from high-grade stainless steel for durability, while the body can be finished with epoxy paint or polished, using stainless steel or carbon steel as required. This ensures superior corrosion resistance and longevity even in challenging environments.Q: Where can these steam jet ejectors be installed?

A: These ejectors are designed for flexible use and can be installed both indoors and outdoors. Their robust construction, weather-resistant finishes, and corrosion-resistant materials make them suitable for a wide range of installation sites.Q: What are the key benefits of using your steam jet ejector?

A: Key benefits include eco-friendly operation with no lubricants required, simple and non-clogging design, low maintenance due to quick disassembly flanges, long service life exceeding 10 years with proper care, and full customizability for application-specific needs.Q: How is maintenance performed on these ejectors?

A: Maintenance is straightforward thanks to quick disassembly flanges, which allow easy access for inspection, cleaning, or component replacement. Routine checks and proper care will help achieve the specified >10-year service life.Q: What process applications can the ejector be used for?

A: These ejectors efficiently serve in distillation units, vacuum packaging lines, chemical processing plants, and power generation facilities, among other uses that require reliable vacuum or gas extraction.Q: When should users consider customizing their steam jet ejector?

A: Customization is recommended when process requirements-such as flow rate, pressure tolerance, material compatibility, or installation configuration-go beyond standard ejector specifications. The design can be fully tailored for optimal integration and performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email