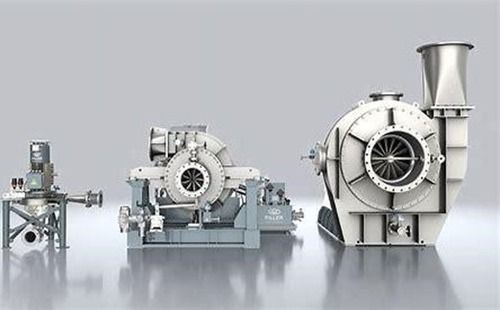

Water jet ejector system

40000 INR/Piece

Product Details:

- Discharge Pressure Up to 8 bar

- Working Temperature -10C to +120C

- Speed 1450 rpm / 2900 rpm

- Noise Level <75 dB

- Inlet/Outlet Flanged / Threaded

- Head Size Up to 50 m

- Theory Jet Ejector Principle

- Click to View more

X

Water jet ejector system Price And Quantity

- 1 Piece

- 40000 INR/Piece

Water jet ejector system Product Specifications

- Industrial fluid transfer, vacuum generation

- Up to 8 bar

- Floor / Skid

- 50 Hz / 60 Hz

- Corrosion resistant, maintenance-free, adaptable for different media

- Up to 7 m

- 5 to 500 m/hr

- Single Stage / Multi Stage

- Mechanical Seal / PTFE / Viton

- Customizable

- Electric powered

- Vacuum/Atmospheric

- Chemical Process / Water Treatment / Pharma / Oil & Gas

- Jet Ejector Principle

- DN25 to DN200

- ISO 9001:2015 / CE

- 380 V / 415 V

- Manual / PLC

- Self-priming

- Stainless Steel / Carbon Steel / PP / PVDF

- Flanged / Threaded

- 1450 rpm / 2900 rpm

- <75 dB

- Up to 50 m

- 0.75 kW to 20 kW

- Up to 8 bar

- Water Jet Ejector

- -10C to +120C

Water jet ejector system Trade Information

- Cash on Delivery (COD)

- Standard

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

Water Jet Ejectors System are devices for the conveyance, compression or mixing of gases, liquids and solids using a gas or liquid driving medium. They operate by the conversion of pressure energy into velocity in suitable nozzles. They are pumps without moving parts.VEPL deals in all types of Vacuum Pump as per client requirement. All material of construction available in this equipment.

Efficient Fluid Transfer with Jet Ejector Principle

Harnessing the power of the jet ejector principle, this system delivers superior vacuum and fluid movement without moving parts. Its tailored engineering ensures rapid start-up, reliable self-priming suction, and compatibility with abrasive or corrosive media, making it a versatile fit for modern industrial requirements.

Robust Construction & Customization

Manufactured with high-grade materials and surface treatments-powder coated, painted, or polished-the ejector system is corrosion-resistant and suitable for demanding environments. Customization options in dimensions, materials, and sealing ensure integration with your existing infrastructure.

FAQ's of Water jet ejector system:

Q: How does the Water Jet Ejector System operate and what fluids can it handle?

A: The system operates on the jet ejector principle, using high-velocity water or steam to create a vacuum and transfer fluids. It is compatible with a range of fluids including water, steam, acids, and solvents, thanks to its corrosion-resistant construction.Q: What installation options are available and where can the system be used?

A: Designed for horizontal installation with ANSI/DIN standard flanges, the system can be mounted on floors or skids and is suitable for applications in chemical processing, water treatment, pharmaceuticals, and oil & gas industries.Q: When should routine maintenance be performed on the system?

A: Routine maintenance is recommended annually or based on usage intensity. The system is engineered for minimal maintenance, supported by robust mechanical or PTFE/Viton seals and a corrosion-resistant finish.Q: What are the advantages of using this water jet ejector system in industrial processes?

A: Key benefits include immediate start-up, self-priming capability, compatibility with hot and cold fluids, high vacuum efficiency up to 95%, and minimal noise below 75 dB. Its durable design ensures over 10 years of service life.Q: How is the Water Jet Ejector System shipped, and what accessories are included?

A: For protection during transit, systems are packed in wooden cases or on pallets. Each shipment includes gaskets, fasteners, and a detailed operation manual for convenient setup and operation.Q: Can the system be customized for specific operational needs and environments?

A: Yes, we offer customization for all dimensions, material selections, and operational parameters to suit unique process requirements and infrastructure compatibility.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email