Stripping column

800000 INR/Unit

Product Details:

- Model No SC-2024 or as specified

- Production Capacity Custom-engineered as per flow rate

- Operating Temperature Ambient to 120C (depending on application)

- Machine Type Industrial Process Equipment

- Control System Automatic / PLC based control (optional)

- Features Corrosion resistant, High separation efficiency, Easy maintenance, Modular design

- Connectivity Options Process lines, instrumentation ports

- Click to View more

X

Stripping column Price And Quantity

- 800000 INR/Unit

- 1 Unit

Stripping column Product Specifications

- Packed Bed / Plate Column

- Process accuracy within 2%

- 50/60 Hz

- 0.5 - 10 HP (as per application)

- <70 dB

- Vertical cylindrical

- External water cooling (optional)

- Electric / Pneumatic pumps

- Depends on size, typically 1 kW and above

- 220/380/415 V (as per customer request)

- Process lines, instrumentation ports

- Corrosion resistant, High separation efficiency, Easy maintenance, Modular design

- 1 to 5 bar (standard) or as per process requirements

- Stripping Column

- Silver / Grey (standard)

- Automatic / PLC based control (optional)

- Industrial Process Equipment

- Electric

- Effluent treatment, solvent recovery, water-gas treatment, ammonia stripping, chemical industries

- Continuous

- Variable, custom-designed to specification

- Ambient to 120C (depending on application)

- SC-2024 or as specified

- Customized as per design

- Custom-engineered as per flow rate

- Polished / Painted / Galvanized

- Depends on size and material, typically ranges from 100 kg to several tons

Stripping column Trade Information

- Cash on Delivery (COD)

- Standred

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

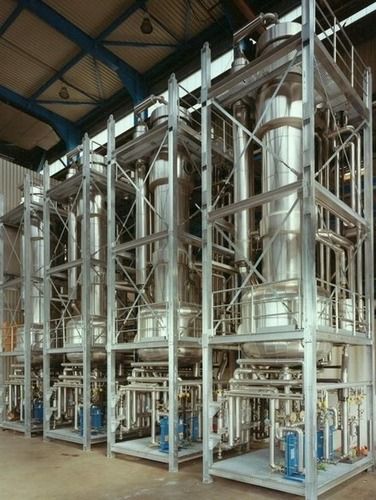

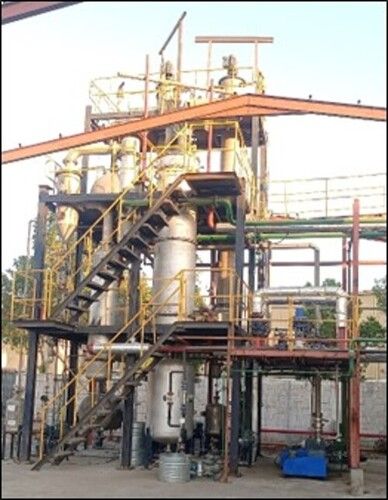

A Stripping Column is a chemical equipment used for physical separation, where one or more components are removed from a liquid stream by a vapor stream. In industrial applications, the liquid and vapor streams can have co-current or counter current flows. Stripping works on the basis of mass transfer.Versatile Material Selection for Durability

Select from stainless steel 304/316, carbon steel, or FRP construction, tailored to your process and corrosion resistance requirements. The vessel thickness ranges from 5mm to 20mm, ensuring structural integrity under demanding operating conditions. These robust materials provide a long service life of over 15 years with minimal maintenance.

Advanced Packing and Tray Options

This stripping column is available with random packing, structured packing, or tray internals, optimizing separation efficiency for various process streams. Whether for chemical processing, water treatment, or gas applications, these internal configurations deliver high mass transfer rates and adaptability to flow variations.

Flexible Design and Customization

Each column is custom-designed to meet individual flow rates, connection sizes (2" to 16" or custom), and dimensional requirements. Surface treatment options include polished, painted, or galvanized finishes. The modular and vertical skid-mounted design ensures quick installation and seamless integration into your processing line.

FAQ's of Stripping column:

Q: How is the appropriate material of construction determined for my application?

A: The selection between stainless steel 304/316, carbon steel, or FRP depends on the chemical nature of the process fluids, temperature, and corrosion conditions. Our engineering team assesses your specific requirements to ensure optimal durability and long-term performance.Q: What types of internals are available, and when should I use packing versus trays?

A: The stripping column can be equipped with random packing, structured packing, or trays. Packing is typically used for continuous, high-efficiency mass transfer in gas-liquid systems, while trays are suitable for processes requiring staged separation. The choice depends on your process goals and physical properties of the fluids.Q: Where are these stripping columns commonly used?

A: These columns are widely implemented in effluent treatment plants, chemical industries, solvent recovery units, water-gas treatment facilities, and for ammonia stripping. They are suitable for both new installations and plant upgrades across diverse industrial sectors.Q: What is the process for installing and commissioning the stripping column?

A: The stripping column is supplied in a vertical, skid-mounted configuration for straightforward installation. After securing to the foundation and connecting process lines, instrumentation ports, and electrical or pneumatic drives, our service team can assist with commissioning and control system calibration.Q: How does the control system enhance operational accuracy and safety?

A: Optional automatic or PLC-based control systems monitor process parameters such as temperature, level, and pressure, ensuring precise operation (within 2% accuracy) and activating safety features like pressure relief valves to protect equipment and personnel.Q: What are the main benefits of using this stripping column?

A: Benefits include corrosion resistance, high separation efficiency, continuous operation, easy maintenance, modular design, and compliance with international standards. The column offers a long operational life and the flexibility to handle varied process conditions and capacities.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email